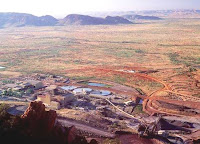

Highland Valley copper/molybdenum mine is located 75km southwest of Kamloops, British Columbia, Canada. The Valley pit has yielded more than 1,100Mt of ore in its lifetime.

Highland Valley copper/molybdenum mine is located 75km southwest of Kamloops, British Columbia, Canada. The Valley pit has yielded more than 1,100Mt of ore in its lifetime.Highland Valley Copper was created as a partnership between Rio Algom and Cominco in 1986 to combine the Bethlehem and Lornex mines. Following the merger between Teck and Cominco in 2001, the 2000 takeover of Rio Algom by Billiton and Billiton's subsequent merger with BHP, the mine was then majority owned by Teck Cominco (63.9%) and BHP Billiton (33.6%). At the beginning of 2004, Teck Cominco exercised its pre-emptive rights over BHP Billiton's holding when the latter put it up for sale, and is now 97.5% owner of Highland Valley.

Production at the mine has decreased significantly the last few years due to an increased reliance on the lower-grade Lornex pit in line with a $C300m mine expansion project designed to push its life expectancy out to 2019. All of the mining equipment required for this work is now on site and commissioned. Highland Valley’s total copper production for 2007 was 136,000 tons, compared to 167,000 tons for the previous year. Molybdenem was just under 4 million pounds compared with just over 4 million for 2006.

Geology and reserves

Highland Valley is a low-grade (0.4% Cu) porphyry copper-molybdenum deposit associated with the younger intrusive phases of the early to mid-jurassic, calc-alkaline Guichon Creek batholith.

Highland Valley is a low-grade (0.4% Cu) porphyry copper-molybdenum deposit associated with the younger intrusive phases of the early to mid-jurassic, calc-alkaline Guichon Creek batholith.As of the end of 2005, proven and probable ore reserves totalled 318Mt grading 0.43% copper and 0.008% molybdenum. Mineral resources added a further 151.9Mt at 0.37% copper and 0.005% moly.

Open-pit mining

Open-pit mining is used in both the Lornex and Valley pits, with around 90% of the ore coming from the Valley pit. Three computerised Bucyrus 49R drills prepare blast hole patterns while nine P&H 4100A 37 yd³ electric shovels load ore into a fleet of Komatsu haul trucks for transport to in-pit crushers. In 2001, eight of the 170t-capacity trucks were replaced by six new 215t haulers. Further support is given by three water trucks, eight road graders, eight tracked bulldozers, three rubber-tyred bulldozers and one front-end loader.

Open-pit mining is used in both the Lornex and Valley pits, with around 90% of the ore coming from the Valley pit. Three computerised Bucyrus 49R drills prepare blast hole patterns while nine P&H 4100A 37 yd³ electric shovels load ore into a fleet of Komatsu haul trucks for transport to in-pit crushers. In 2001, eight of the 170t-capacity trucks were replaced by six new 215t haulers. Further support is given by three water trucks, eight road graders, eight tracked bulldozers, three rubber-tyred bulldozers and one front-end loader.The mine uses two semi-mobile in-pit crushers to minimise haul distances. Several kilometres of conveyors carry up to 12,000t/h of crushed ore to three stockpiles at the Highland mill. Pit operations are monitored and controlled by a Modular Mining Systems computerised dispatch system designed to maximise mine production. In addition minute-by-minute mapping is achieved by combining GPS navigation and survey with GIS mapping techniques.

Ore processing

The Highland mill, the world’s third largest copper concentrator, was constructed in the late 1980s by combining the original Lornex and Highmont mills. The complete Highmont mill was moved by road 10km from its former site to a new position adjacent to the Lornex plant.

The Highland mill, the world’s third largest copper concentrator, was constructed in the late 1980s by combining the original Lornex and Highmont mills. The complete Highmont mill was moved by road 10km from its former site to a new position adjacent to the Lornex plant. Copper concentrate is transported in bulk 40km to the rail yard at Ashcroft, then by rail to north Vancouver and finally by ship to overseas smelters. The molybdenum concentrate is packaged on site for shipment.

Copper concentrate is transported in bulk 40km to the rail yard at Ashcroft, then by rail to north Vancouver and finally by ship to overseas smelters. The molybdenum concentrate is packaged on site for shipment.Environment

In 1997, Highland Valley Copper was presented with the 1996 British Columbia Reclamation Citation Award in the metal mining category for its outstanding achievement in reclaiming 1,000ha and planting 700,000 native trees and shrubs. Work to establish fish stocks in different water bodies on the property is continuing to be successful.

In 1997, Highland Valley Copper was presented with the 1996 British Columbia Reclamation Citation Award in the metal mining category for its outstanding achievement in reclaiming 1,000ha and planting 700,000 native trees and shrubs. Work to establish fish stocks in different water bodies on the property is continuing to be successful.Production

As noted in the overview above, production at Highland Valley has declined significantly the last few years. Teck Cominco recently downgraded its production guidance for the 2008 full year from an initial 122,000 tons to 113,000 tons. Highland Valley’s total copper production for 2007 was 136,000 tons, compared to 167,000 tons for the previous year. Molybdenem was just under 4 million pounds compared with just over 4 million for 2006. Total ore mined fell also to 42.6Mt.

Teck Cominco has stated that mining of areas with higher clay content will continue throughout 2008 and 2009. Just over half of the total ore mined for Q3 2008 came from the lower grade Lornex mine compared with only 41% for the 5% to 30,500 tons.

The future

Waste stripping for Highland Valley's $C300m mine life extension is continuing with the pushback of the east wall in the Valley pit progressing well despite a minor geotechnical failure in the third quarter which is currently being rectified.

All the equipment is on site, permits received and contractors arranged. The pushback of the west wall necessary to extend the mine life to 2019 is scheduled to commence in early 2009 after the mine permit amendment received.